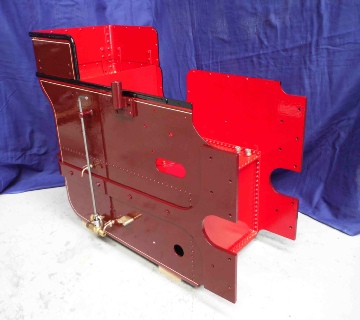

The tender is the rear of the traction engine, and has the coal bunker, the footplate, and the water tank underneath.

The tender came as two kits. Unfortunately, STW’s production schedules got mucked

up, and instead of being a month apart, there was a two-

The straight lengths of beading along the top edge were rounded,but the curved bits around the step and on the coal bunker top section were flat. I had to round these off with the angle grinder to match; quite tricky in the tighter curves!

The tender is assembled using 283 M3 screws disguised as rivets (you have to grip

the round head with pliers whilst tightening the nut because there’s no slot). Once

the structure was complete, I had to seal the tank, using a proprietary motorbike

petrol tank sealing kit. Being made of sheet steel, it was quite gappy. First I sealed

up all the screw holes and pipe inlets and outlets.With Adam’s help to turn the tank

all around, I slooshed the inside with de-

I was then able to do the painting. Again it was the “Burrell Plum” on the outside, with Alfa Red inside.

Some of the lining was straightforward, being nice straight lines, but then came the curves and corners! I couldn’t use the lining tape as such because it doesn’t bend; I had to cut it down the middle and stick the two edges separately and get the gap by eye. The tight corners I had to do freehand using the painting pen.

Once it was all painted and varnished, I put the fittings on. The brasswork needs polishing up, but the steel bits such as the water valve handle will need nickel plating once I have enough parts to make the cost worthwhile.

The brackets at the back end are for the winch cable rollers. I haven’t fitted the rollers yet, as they also need plating.

KITS 7-

1/3-